Active & intelligent packaging – the AIPIA Congress 2022 Review

A key takeaway of mid-Nov outcome, was the growing commitment past brands to develop packaging which communicates, not only with consumers only all along the supply chain, to ensure security and efficiency. This special report by Andrew Manly, communications manager of AIPIA discussed how smart packaging technology is spreading across the packaging landscape.

The Active & Intelligent Packaging Industry Association (AIPIA) held its chief event of the year in mid-Nov with the overarching theme of the Digitization of Packaging with a special focus on connected packaging and supply chain issues. With 36 speakers in a packed 5-hour virtual plan, the topics covered everything from smart labels, combining NFC/RFID, data admission and management, to active materials and tags.

A key takeaway, co-ordinate to AIPIA, was the growing commitment by brands to develop packaging which communicates, non only with consumers but all along the supply chain, to ensure security and efficiency. Other important outcomes were the growth of augmented reality and the demand to communicate across all stakeholders, even within private companies, in a common 'language' and how to go across key messages well-nigh the benefits of these technologies. Standardization and stability of technological developments, to enable scalable solutions, was too a talking point

"The industry is at present more confident about discussing the challenges it faces, as well every bit highlighting the obvious progress it has made," said AIPIA managing manager Eef de Ferrante. "In a perverse way the pandemic has enabled the sector to highlight the need for stronger supply chain direction, better customer and internal advice, contactless transactions and the dangers of counterfeiting in the earth of on line purchasing and eCommerce."

"Simply nosotros must recognize that the take upwards of Smart Packaging is still slower than we would expect and address the reasons why. Several presentations and give-and-take rooms at the event did just that. Also, l am thrilled to announce we are working with Accenture, the global consulting group, to develop ways to accelerate the implementation of our technology and make more noise well-nigh it," he added.

In her opening address to the Congress, Accenture'southward Anita Etrati explained that the consultancy will be publishing its Smart Packaging Bespeak of View – Transforming the ordinary with smart connected packaging , in the coming months. Information technology will be in collaboration with AIPIA and its members and focus on the misconceptions companies concur around smart continued packaging and the steps they need to take to succeed.

consultancy will be publishing its Smart Packaging Bespeak of View – Transforming the ordinary with smart connected packaging , in the coming months. Information technology will be in collaboration with AIPIA and its members and focus on the misconceptions companies concur around smart continued packaging and the steps they need to take to succeed.

"Smart connected packaging provides digital touchpoints at every stage of the product lifecycle. Information technology helps brands deliver exceptional customer experiences that delight and reach ongoing operational value. And it involves an ecosystem of powerful technologies, which drive new modes of production interactivity," explained Etrati.

Telling the story of how his company has evolved the SmartLabel was the key theme of John Phillips, SVP, Customer Supply Chain & Global Go-To-Marketplace at PepsiCo and one of its main platform development partners, Scanbuy in the opening keynote. He explained how the SmartLabel initiative started out in the USA as a customer transparency projection to offer far more than information digitally than could be put on a normal characterization. Information technology has evolved to now include information such every bit regulatory information and become beyond that past creating genuinely smart packaging which can have 'curated content' for the individual brand and product via what PepsiCo is calling an Intermediate Menu.

GSI Digital Code probable to supervene upon Unique Product Codes

The 20 or so companies working on the SmartLabel project through the Consumer Brands Association anticipate that in v to 7 years the unique product codes (UPC) volition exist replaced by a QR lawmaking which will have all the functionality of the UPC plus everything else a smart pack requires. The project anticipates that the GSI Digital Code will be the prime number vehicle for this rollout.

Maryann Moschides, Scanbuy's CMO and general manager explained that its digital platform, which is already in use past many major brands to provide tailored information for consumers, has seen a dramatic pandemic issue, with 162% growth in unique consumers engaging with QR codes between January 2022 and October 2021. In improver, the company candy xix% more unique user scans between January and September 2022 and from Q3 2022 to Q3 2022 saw a 29% increase in packaging appointment. Phillips said in the last half dozen months, SmartLabel pages on PepsiCo brands had received v.6 million visits, a stiff upward trend.

This is probably not only accounted for by the pandemic, equally consumers become much more familiar with accessing information via smartphones. Indeed a recent US survey by Acosta establish that 6 in 10 shoppers are at present comfortable using digital tools while shopping.

Sustainable traceability and patient compliance for pharma

With pharmaceutical traceability and patient compliance loftier on the agenda, the talk given by Roberto Lattuada, CEO of myHealthbox had a topical subject, which echoed the sustainability issues too. The patient information leaflet is going digital he proposed. The objective is to make the use of medicines safer by offering up-to-date instructions electronically (then no need for a newspaper leaflet) available on any device.

While various regions are at unlike stages of the transition to electronic product information (EPI) the need for pharma companies globally to have a strategy in place to transition from paper to this format is imperative, he contends. Europe is well down the route in this respect with Japan non far behind, while USA and Canada are in the initial stages.

The benefits of this truly connected packaging idea are very potent, he claims, greener, safer and smarter – so information tin can be updated easily and in multi-language versions. In one of the two example studies, he offered a company was able to achieve considerable toll saving by only having a local marketplace language leaflet (printed on recyclable paper) with all other languages available via the EPI.

Can smart and sustainable co-exit?

Matt Morris sustainability lead and Pari Gaikwad, head of Digital, both from Cambridge Design Partnership, chose Smart Sustainable Packaging Innovation as their subject. Pari opened by posing the question 'Can Smart and Sustainable co-exist'? Matt showed an example of where even 'legacy' packaging is nether review and how the United kingdom's largest food retailer, Tesco'south pack for chicken proteins, has been changed from black plastic to light gray to brand information technology easier to sort in the recycling chain. But with an RFID tag attached to a standard water canteen calculation 10% to the carbon footprint of the pack, how can brands sell the concept of using tags to their stakeholders, he asked?

The reply is to focus on the intersection between smart and sustainable, says CDP and demonstrate the benefits that bring beyond just the packaging itself. An obvious winner in the current Covid-nineteen world is the apply of traceability and tracking devices to monitor vaccine distribution. Some other clear benefit is to apply connected packaging to encourage sustainable behaviour, such as improved medicine compliance and better recycling habits to reduce waste material of both the production and the pack. An case of encouraging re-use is ClubZero a very utilitarian drink container using an RFID tag to rails the containers and go far user-friendly to driblet them off at any of a number of recycling points. Information technology works beyond retailers, so ideal for smaller outlets in loftier-density locations.

The presentation concluded by being clear that dissimilar packs and products would require unlike smart engineering solutions and, in the sustainability arena, the fox is to choose the most low touch solution for the given requirement. In improver, advances in smart packaging technologies, such equally printed integrated circuits can profoundly reduce the carbon footprint when compared to silicon-based RFID tags. Overall Matt concluded this talk with 1 of the more memorable comments of the outcome – smart packaging and sustainable packaging are not necessarily oxymoronic!

The founder of Specright, Matthew Wright talked about the Transition of Packaging to a digital world through information. He spoke near the current situation where different components of the bundle for a single production all can have unlike specifications in many different silos, making interoperability very hard. The explosion in the number and variety of SKUs, increased regulatory and sustainability requirements, lack of visibility in the supply chain and the need for avant-garde supply concatenation analytics make it imperative to take common, digitized specification information.

His software solution, he claims, enables the digitization of the packaging value concatenation by digitizing the specifications, linking these across the supply concatenation network, layering analytics, workflows and approvals and finally networking the results to permit sharing and updating across all the stakeholders. Accrued benefits include profoundly reducing the 'on-boarding' of a new supplier or meeting spikes in need for the product. One client, a major cosmetics company, has been able to progress its 5-twelvemonth sustainability commitment by benchmarking production and packaging material used, measuring progress and executing necessary changes.

The Holy Grail 2.0 projection

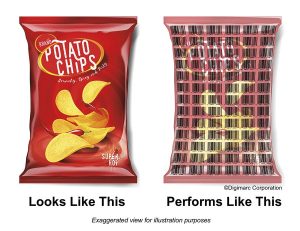

Several presentations mentioned the Holy Grail 2.0 project which was initiated past a group of 140 companies covering both suppliers and users, led past Proctor & Hazard, to greatly increase the recyclability of plastics by identifying different types of material through a digital watermarking procedure. Larry Logan, packaging evangelist at Digimarc, which has developed the watermark engineering science, provided delegates with an update on the project.

Following successful validation of the technology in 2020, semi-industrial testing has been going on at two sites this year involving more than 232 SKUs and 120,000 samples, including HDPE and PET bottles and 2d labels and 3D. Results of these trials are due before long. The next phase is full industrial testing in 2022, at sites in France and Federal republic of germany. A link to the semi-industrial trial test results has been available at https://www.digitalwatermarks.eu/openhouses since 18 November.

During the Congress two other recycling initiatives were covered. Johan Kerver, chief

executive officeholder of Filigrade Sustainable Watermarks outlined CurvCode, a European watermarking technology for sorting nutrient and non-food plastics. Ivan Gonzalez, master executive officer of Recycl3R introduced a Global Brotherhood to promote a Packaging Digital Deposit and Refund System (Digital DRS) through serialised and connected packaging.

With such a diverse range of Smart Packaging technologies explored across the Congress,

including the touch of combined NFC + RAIN RFID labels (Checkpoint Systems), battery-free Bluetooth tags (Wiliot), active packaging for nutrient and pharmaceutical safety (Aptar CSP and ITENE), Blockchain (Magic Advertisement and 3D) likewise every bit several outstanding contributions on Traceability (Kezzler/Arviem, Systech, Digimarc) it is clear that the Digitization of Packaging (supply bondage in particular) is continuing at an increasingly fast pace.

Make owners must focus on the benefits of these technologies and where they can fit into their product portfolio-landscape – to run across the increasing demands for greater client transparency and engagement as well equally to improve traceability and security. In that location is a compelling case emerging that, rather than being a hindrance to sustainability, smart packaging can be a real aid.

Summing upwards the Congress Eef de Ferrante said, "It is very encouraging that the stride of development and innovation and the levels of involvement in smart packaging technology seems to accept increased again. While implementation may have been deflected past other issues, such as reformulating of packs and products to run across sustainability goals, there are signs that we are very much back on the Make Owners' agenda. Nosotros expect forward to getting back to a larger, dynamic live event in 2022!"

Source: https://packagingsouthasia.com/active-and-intelligent-packaging/aipia-congress-2021/

0 Response to "Active & intelligent packaging – the AIPIA Congress 2022 Review"

Post a Comment